Smart Factory

Home

Home- Smart Factory

- QRP Solutions

- QRP-STD

QRP Solutions

핵융합반응은 핵분열반응과 상반되는 물리현상으로 수소와 같이 가벼운 원소들의 핵들이 서로 결합하여 헬륨과 같은 좀 더 무거운 원소의 핵을 형성하는 현상이며 이때에 질량결손에 의해 생겨나는 에너지는 방출되는 입자들의 운동에너지로 나오게 되는데 이를 발전(發電)에 응용하는 연구가 핵융합연구개발입니다.

즉, 1억 5,000만℃ 이상의 고온에서 가벼운 원자핵이 융합하여 더 무거운 원자핵이 되는 과정에서 에너지를 창출해 내는 방법으로,

이러한 핵융합 반응을 연쇄적으로 일으켜 폭발에 이르게 하면 수소폭탄이고, 이를 제어해 에너지화 하는 것이 핵융합 발전입니다.

Mobiis has developed technological solutions and provided services to the nuclear fusion community since our first participation in the ITER Project in 2012.

During more than a decade, working in close collaboration with plasma scientists and fusion experts in Korea and all around the world,

our engineers and scientist have contributed to create the control tools that will be esential to operate the future power plants,

which will be based on the same source of energy that powers the Sun.

가속기는 전자, 양성자 또는 이온과 같은 전하를 띈 입자를 전자기장을 이용하여 빛의 속도에 가깝게 가속시킨 후 방사광을 발생시키거나 다른 입자와 충돌시키는 방법 등을 이용하여 원자핵 내부나 소립자의 미세 구조 등을 연구하고

새로운 희귀동위원소를 만들어내는 장치입니다.

모비스는 가속기 제어에 핵심이 되는 장비 및 시스템(LLRF, SSA, BPM, Cryo모듈, Undulator 등)을 공급하고 있습니다.

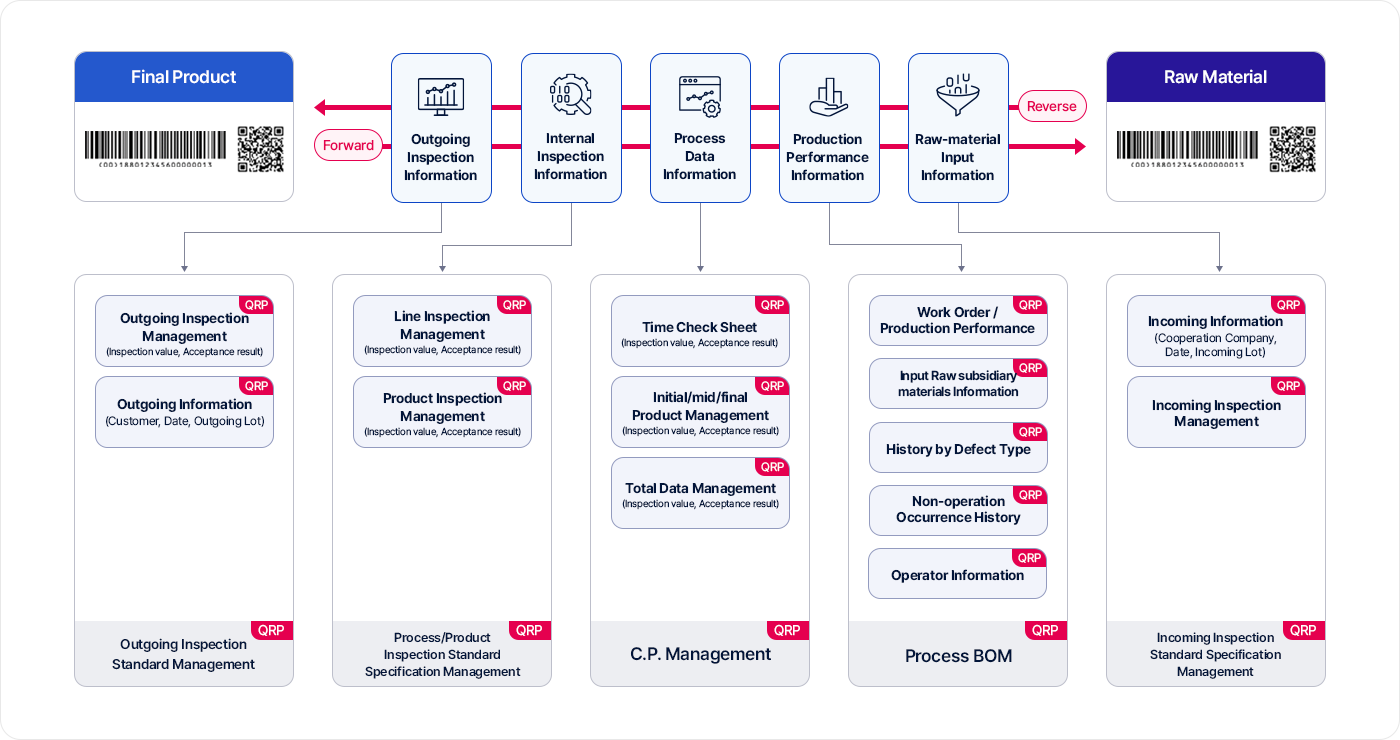

QRP-STD supports Lot Tracking.

- SCADA/HMI (Ignition, In-touch, CIMON)/PLC and interface, inspection/measurement equipment and Interface support

- Interface for field equipment is linked with management plan and work order

- Tracking of equipment conditions, production performance, and inspection performance data by work order, lot, and serial

QRP-STD is a solution that can be installed with minimal cost.

- It is a package-based solution and supports operation after setting for about 4 weeks

- Support for minimizing the installation period in the order of company selection → preparation → installation → basic data registration → training → operation

- However, essential development items such as SCADA/HMI/PLC serial communication, BarCode label, and shipment report are supported for development

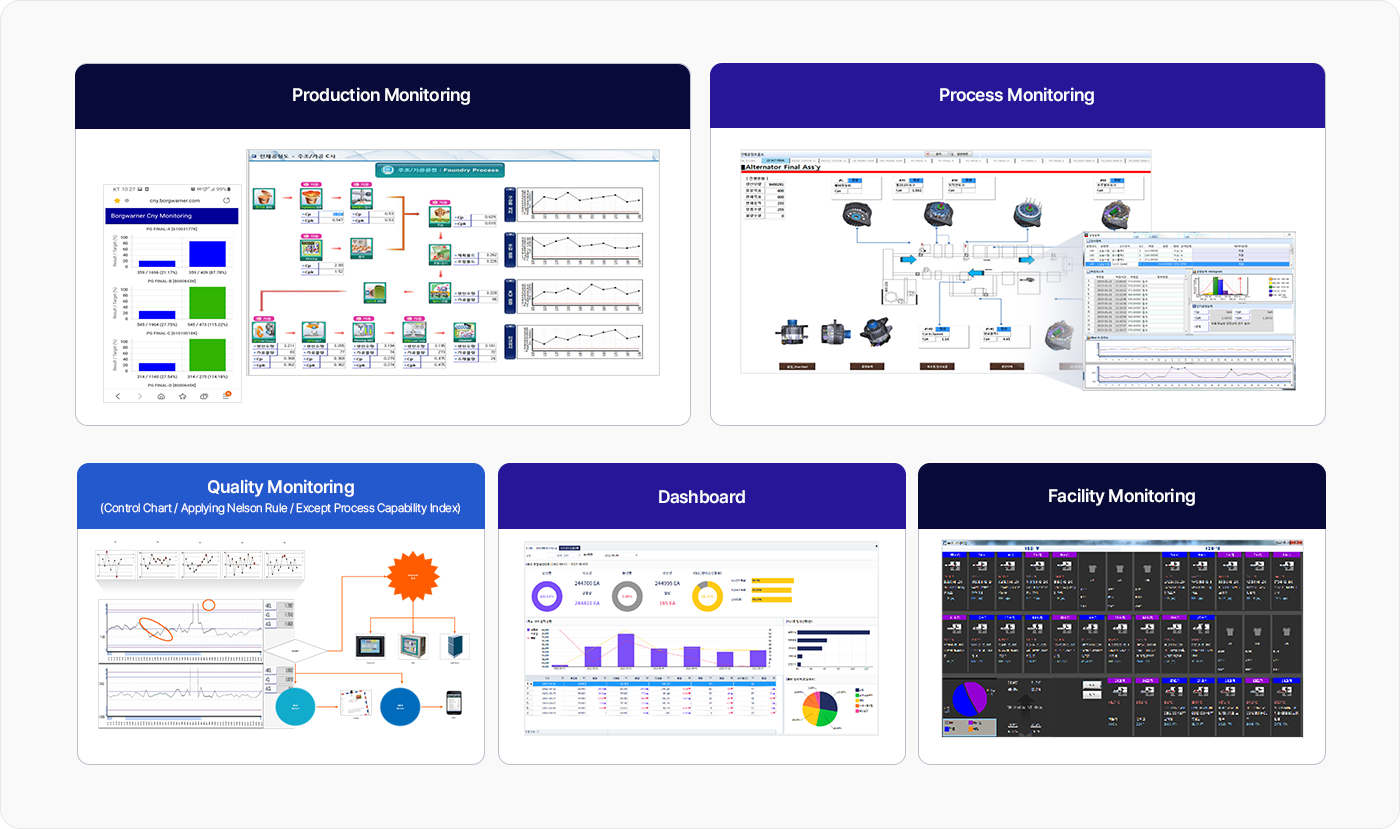

QRP-STD supports production/process/quality monitoring.

- Real-time monitoring of production performance/facility status/quality status and SPC and process capability Analytics support

- Real-time SPC and process capability analysis support by linking collected data with management plan and standard information

- In the event of an error, immediate notification through SMS and E-Mail and linkage support with OCAP and nonconformity management

The function of QRP-STD can be selected according to the scale of management.

- QRP STD can be selected as a license type according to the management scale of the introducing company

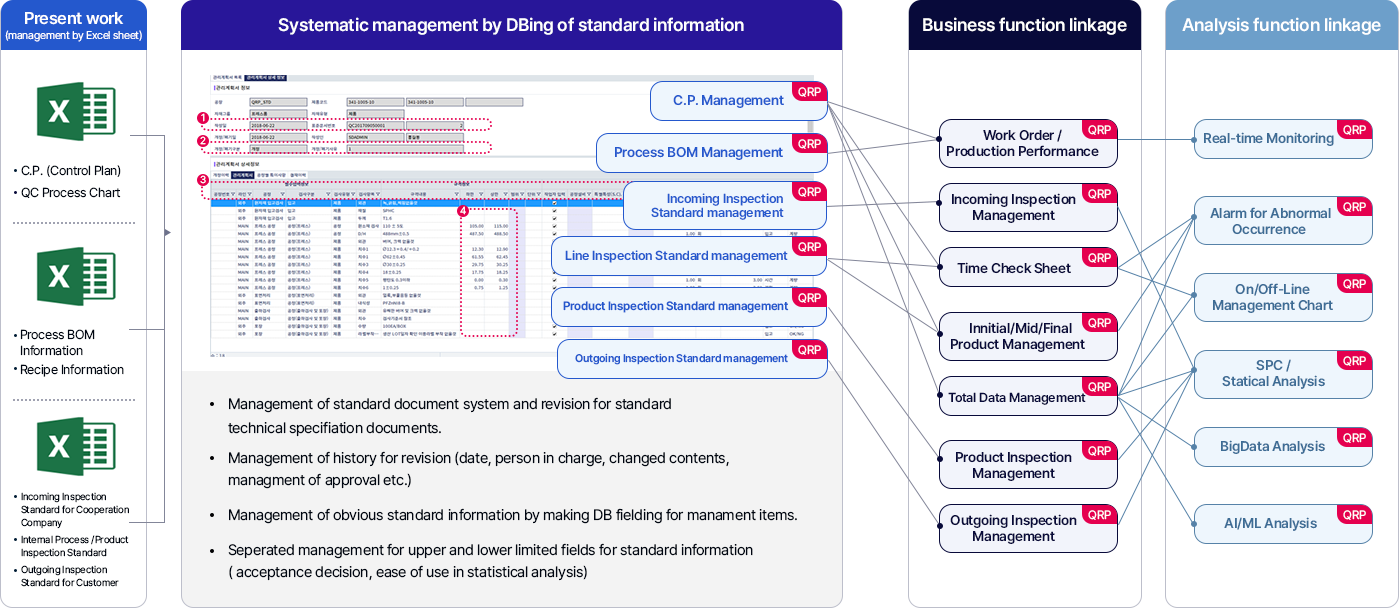

QRP-STD supports IATF Core Tool.

- Support major tasks in the design stage-mass production stage with QMS modules

- Core tool (APQP, FMEA, C.P, PPAP, MSA, SPC) suppor

- Support for ISIR, 6M, claims, quality evaluation, EO, partner management, etc

QRP-STD supports equipment & mold management.

- Support TBM activities such as preventive maintenance (PM) for facilities, post-maintenance (BM), maintenance material management, etc

- Life span management support by mold shot number, mold manufacturing and mold repair management support

- Support asset history management for facilities and molds

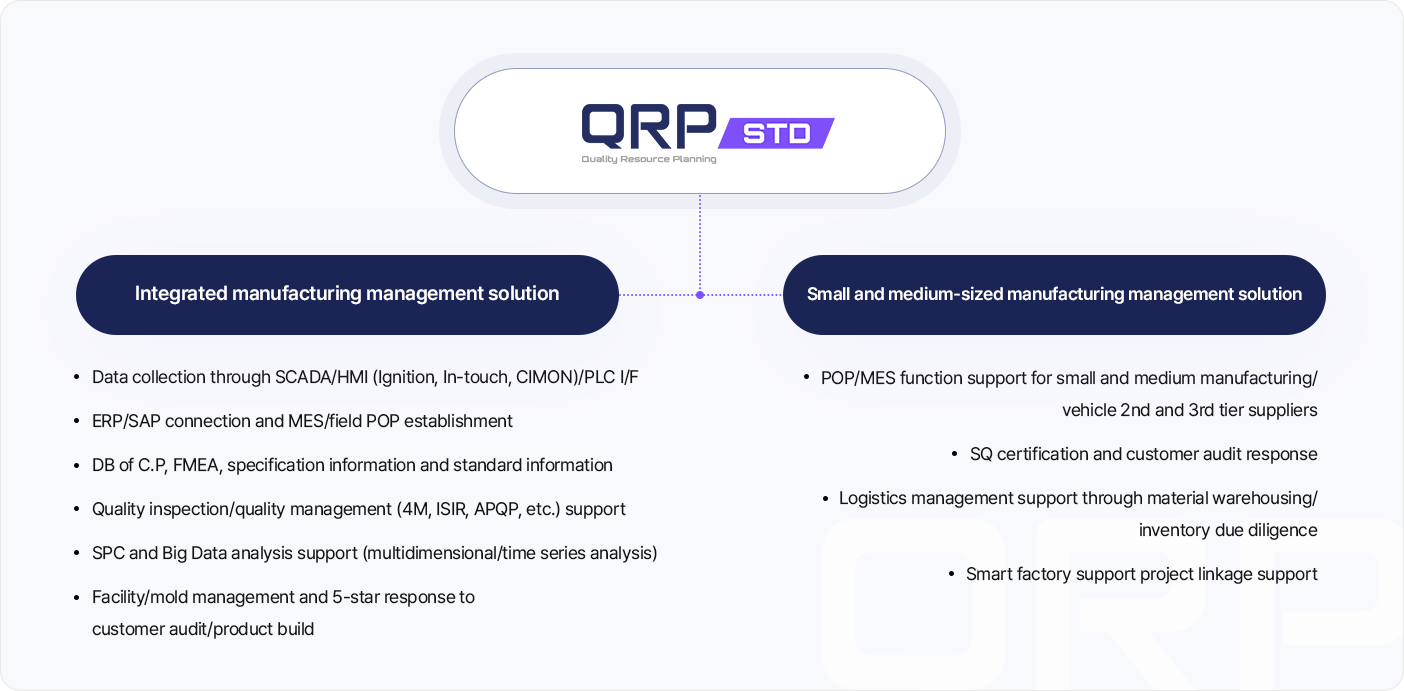

QRP-STD is the optimal solution for small and medium-sized manufacturing companies.

- Among the functions of QRP V3.0, only essential functions necessary for SMEs are selected and configured

- Applied in connection with the smart factory establishment support project for small and medium-sized enterprises

Mobiis core business, together with solutions for nuclear fusion tokamaks, is the development and construction of high-quality

hardware and software solutions for the reliable, safe and efficient operation of particle accelerators.

Mobiis is the main supplier of control software tools and beamline instrumentation hardware for all the particle accelerators currently in operation and under construction in South Korea. The Pohang 4th Generation Light Source (PAL) and the Daejeon Heavy Ion Accelerator (RAON),

as well as RAON and other domestic medical and industrial accelerators, run with software and hardware solutions developed by Mobiis engineers.

Mobiis is also present in international particle accelerator projects such as the European Spallation

Source in Sweden, the ALBA synchrotron in Spain and the ISIS neutron source in the United Kingdom.